The Role of PFA Lined Valves in Ensuring Safety and Compliance in Industrial Applications

Introduction

Industrial applications require robust and reliable valve solutions to handle aggressive chemicals, extreme temperatures, and high-pressure environments. PFA (Perfluoroalkoxy) lined valves have emerged as a critical component in industries such as chemical processing, pharmaceuticals, water treatment, and oil and gas. These valves provide superior corrosion resistance, chemical inertness, and compliance with stringent safety regulations. This article explores the role of PFA lined valves in ensuring safety and regulatory compliance in industrial applications.

Understanding PFA Lined Valves

According to a PFA Lined Valves Market report, the industry is expected to grow significantly in the coming years.

PFA lined valves are industrial valves that feature an internal lining of perfluoroalkoxy, a high-performance fluoropolymer known for its exceptional chemical resistance and mechanical stability. This lining protects the valve body from corrosive substances, ensuring long-term durability and operational reliability. PFA lined valves are commonly used in applications where standard metal or plastic valves would fail due to aggressive media exposure.

Get More Info:

Key Benefits of PFA Lined Valves

1. Superior Chemical Resistance

PFA is highly resistant to a wide range of corrosive chemicals, including strong acids, alkalis, and organic solvents. This resistance makes PFA lined valves ideal for handling hazardous substances without degradation or contamination risks.

2. High-Temperature Tolerance

Unlike other polymer linings, PFA can withstand elevated temperatures up to 260°C (500°F), making it suitable for processes involving high thermal stress.

3. Enhanced Mechanical Strength

PFA combines the flexibility of PTFE (Polytetrafluoroethylene) with the mechanical strength of FEP (Fluorinated Ethylene Propylene), providing excellent impact resistance and structural integrity under demanding conditions.

4. Leak Prevention and Safety Assurance

5. Compliance with Industry Standards

PFA lined valves comply with international safety and environmental standards, including ISO, ANSI, ASTM, and API specifications. These valves meet stringent requirements for chemical handling, ensuring regulatory compliance in industrial settings.

What Are PFA Lined Valves?

PFA (Perfluoroalkoxy alkane) lined valves are industrial valves that have their internal surfaces lined with PFA, a type of fluoropolymer. PFA is chemically similar to PTFE (commonly known as Teflon) but has better mechanical strength and higher processability. This makes PFA an ideal lining material for valves that control aggressive fluids or are used in highly pure applications.

These valves combine the mechanical strength of metal valve bodies—usually stainless steel or ductile iron—with the chemical inertness of PFA lining. The result is a valve that withstands harsh chemicals and high temperatures while maintaining structural integrity.

Why Use PFA Lined Valves?

1. Exceptional Chemical Resistance

PFA is virtually inert to most chemicals, including strong acids, bases, and solvents. This makes PFA lined valves ideal for applications involving:

-

Sulfuric acid

-

Hydrochloric acid

-

Sodium hydroxide

-

Chlorine gas

-

Organic solvents

In industries like chemical processing and water treatment, where fluid corrosion is a major concern, PFA lining significantly extends valve lifespan.

2. High-Temperature Tolerance

PFA lined valves can operate at temperatures up to 260°C (500°F). This is especially useful in processes involving steam, high-temperature acids, or solvent recovery, where traditional rubber or metal components would fail.

3. Smooth Surface and Purity

PFA has an ultra-smooth surface, minimizing contamination and particle entrapment. This is vital in industries like:

-

Pharmaceuticals: Where product purity and regulatory compliance are critical.

-

Semiconductors: Where even microscopic contamination can affect performance.

-

Food and Beverage: Where cleanliness and food safety are essential.

4. Mechanical Strength and Leak Prevention

Unlike solid plastic valves, PFA lined valves retain the structural advantages of metal. The PFA lining is bonded to the internal surface of the valve body, providing:

-

High pressure ratings (up to 16 bar or more)

-

Resistance to mechanical stress

-

Leak-proof performance even under cycling and vibration

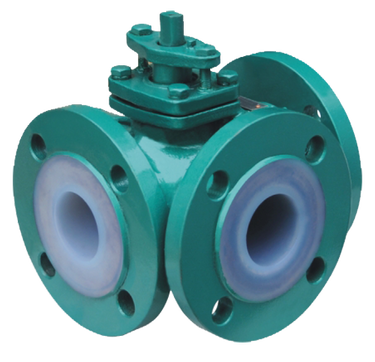

Common Types of PFA Lined Valves

1. PFA Lined Ball Valves

These offer tight shut-off and are commonly used for on/off control of fluids. Their design is simple, reliable, and allows for minimal pressure drop.

2. PFA Lined Butterfly Valves

These are ideal for large-diameter pipes and applications where compact design and low cost are desired. Butterfly valves are suitable for throttling as well as shut-off service.

3. PFA Lined Diaphragm Valves

Preferred in pharmaceutical and food industries, diaphragm valves offer excellent cleanliness and are often used in sanitary applications. The lining helps in avoiding dead zones and contamination.

4. PFA Lined Plug Valves

These valves provide tight shut-off and are suitable for handling highly corrosive fluids. Their simple design allows for easy maintenance and reliable operation.

5. PFA Lined Globe Valves

Used for flow regulation, these valves offer precise control. The PFA lining protects the metal body while the globe design handles throttling efficiently.

Applications of PFA Lined Valves

1. Chemical Processing

In chemical plants, PFA lined valves are used for handling highly corrosive substances such as sulfuric acid, hydrochloric acid, and sodium hydroxide. Their corrosion-resistant properties ensure the longevity and safety of processing equipment.

2. Pharmaceutical and Biotechnology

The pharmaceutical industry requires high-purity systems to prevent contamination. PFA lined valves provide a hygienic and inert solution for handling sensitive chemicals and biopharmaceutical products.

3. Water Treatment Plants

Municipal and industrial water treatment facilities use PFA lined valves to control the flow of aggressive chemicals such as chlorine, ozone, and fluorides, ensuring efficient and safe water purification processes.

4. Oil and Gas Industry

In the oil and gas sector, PFA lined valves play a vital role in managing corrosive fluids, acids, and hydrocarbons during drilling, refining, and transportation operations.

5. Food and Beverage Processing

PFA lined valves are used in food processing applications where contact with strong cleaning agents and acidic substances requires non-reactive and food-safe valve solutions.

Ensuring Compliance and Safety with PFA Lined Valves

1. Adherence to Environmental Regulations

PFA lined valves comply with environmental regulations, reducing the risk of hazardous chemical leaks that can lead to regulatory penalties and environmental damage.

2. Improved Workplace Safety

By preventing corrosion-related failures, PFA lined valves enhance worker safety by minimizing exposure to toxic chemicals and reducing the likelihood of accidents.

3. Extended Equipment Lifespan

The durability of PFA lined valves reduces maintenance costs and extends the lifespan of industrial systems, ensuring long-term compliance with operational safety standards.

Conclusion

PFA lined valves play a crucial role in ensuring safety, efficiency, and regulatory compliance across various industries. Their superior chemical resistance, high-temperature tolerance, and mechanical strength make them indispensable in handling corrosive and hazardous substances. By incorporating PFA lined valves into industrial systems, companies can achieve enhanced safety, reduced maintenance costs, and compliance with industry regulations, ultimately improving operational efficiency and sustainability.